|

Gongyi Mchinery Factory

|

Jaw Crusher for Sale in 2014

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Jaw crusher is widely used in mining, building materials, high way, railway, water conservancy and chemical industry etc.

Description

Jaw crusher is widely used in mining, building materials, high way, railway, water conservancy and chemical industry etc. It is always used for crushing granite, limestone, cement, quartz etc. soft and hard rocks and ores.

As for the character of high crushing ratio, uniform production size, simple structure and easy maintenance, Jaw crusher is very popular in mining crushing site. Many mining operators choose jaw crushers as the busic primary crushing equipments.

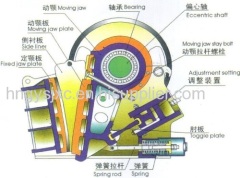

Jaw crusher is mainly composed of machine base (cabinet), eccentric shaft, pulley, jaw plate, connecting rod, regulating mechanism and the locking spring and other parts.

Working principle of Jaw Crusher:

Motor drive v-belts transfer power to the belt pulley. Then the pulley eccentric shaft makes the upper parts of dynamic jaw plate moving around eccentric shaft and this movement might cause the whole dynamic jaw move up and down. When dynamic jaw rises,the angle between the bracket and fixed jaw will be larger, so as to promote dynamic jaw plate to the fixed jaw plate. At the same time, the material will be crushed or cut (chopped) to achieve the purpose of crushing; When the moving jaw moves downward, angle between bracket and dynamic jaw wille be smaller. Under the pressure of the spring and bar, dynamic jaw plate will leave the fixed jaw plate, and then broken material will be pished out from crushing cavity .

Technical Parameters of Jaw Crusher

| Model | Feed Opening (mm) | Max. feeding size (mm) | Adjusting range of discharge opening (mm) | Capacity (t/h) | Rotation speed of eccentric shaft (r/min) | Motor power (kw) | Total weight (t) | Dimensions (L*W*H)(mm) |

PE-150*250 | 150*250 | 125 | 10-40 | 1-3 | 250 | 5.5 | 0.8 | 720*660*850 |

PE-200*300 | 200*300 | 180 | 15-50 | 2-6 | 260 | 7.5 | 1.2 | 910*750*990 |

PE-200*350 | 200*350 | 180 | 18-70 | 3-10 | 260 | 11 | 1.5 | 1000*870*990 |

PE-250*400 | 250*400 | 210 | 20-60 | 5-20 | 300 | 15 | 2.8 | 1300*1090*1270 |

PE-400*600 | 400*600 | 340 | 40-100 | 16-60 | 275 | 30 | 7 | 1730*1730*1630 |

PE-500*750 | 500*750 | 425 | 50-100 | 40-110 | 275 | 55 | 12 | 1980*2080*1870 |

PE-600*750 | 600*750 | 500 | 150-200 | 80-240 | 275 | 55 | 15.8 | 2070*2000*1920 |

PE-600*900II | 600*900 | 500 | 65-160 | 50-180 | 250 | 55 | 17 | 2190*2206*2300 |

PE-750*1060 | 750*1060 | 630 | 80-140 | 110-320 | 250 | 110 | 29 | 2660*2430*2800 |

PE-800*1060 | 800*1060 | 640 | 130-190 | 130-330 | 250 | 110 | 29.8 | 2710*2430*2800 |

PE-830*1060 | 830*1060 | 650 | 160-220 | 150-336 | 250 | 110 | 30.7 | 2740*2430*2800 |

PE-870*1060 | 870*1060 | 660 | 200-260 | 190-336 | 250 | 110 | 31.5 | 2810*2430*2800 |

PE-900*1060 | 900*1060 | 685 | 230-290 | 230-390 | 250 | 110 | 33 | 2870*2420*2940 |

PE-900*1200 | 900*1200 | 750 | 95-165 | 220-450 | 200 | 110 | 52 | 3380*2870*3330 |

PE-1000*1200 | 1000*1200 | 850 | 195-265 | 315-500 | 200 | 110 | 55 | 3480*2876*3330 |

PE-1200*1500 | 1200*1500 | 1020 | 150-350 | 400-800 | 180 | 160-220 | 100.9 | 4200*3300*3500 |

PE-1500*1800 | 1500*1800 | 1200 | 220-350 | 500-1000 | 180 | 280-335 | 122 | 5160*3660*4248 |

PE-1800*2100 | 1800*2100 | 1500 | 300-400 | 1300-2200 | 160 | 350-380 | 150.6 | 6210*4013*4716 |

PEX-150*750 | 150*750 | 120 | 18-48 | 8-25 | 320 | 15 | 3.8 | 1200*1530*1060 |

PEX-250*750 | 250*750 | 210 | 25-60 | 13-35 | 330 | 30 | 5.5 | 1380*1750*1540 |

PEX-250*1000 | 250*1000 | 210 | 25-60 | 16-52 | 330 | 30 | 7 | 1560*1950*1390 |

PEX-250*1200 | 250*1200 | 210 | 25-60 | 20-61 | 330 | 37 | 9.7 | 2140*1660*1500 |

PEX-300*1300 | 300*1300 | 250 | 20-90 | 16-105 | 300 | 55 | 15.6 | 2720*1950*1600 |

.jpg)