|

Gongyi Mchinery Factory

|

Magnetite Ore Dressing - Gongyi Machinery Factory

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Magnetite is a kind of iron ore, steel is tried one of the main raw materials.

Introduction of Magnetite Mineral processing equipment :

Magnetite is a kind of iron ore, steel is tried one of the main raw materials. Magnetite Mineral processing equipment The steel industry and national economy in China is the main industry, in relation to many of the relevant industries survival and development, are much various sectors of concern and support. Process Of Mining Iron Ore Gongyi Machinery is specialized in the production of professional manufacturers magnetite milling equipments, The following is Gongyi Machinery factory according to years production magnetite mines on-the-spot investigation and mineral processing equipment experience with mineral processing magnetite comprehensive experience.

Magnetite Mineral processing equipment process:

The main mineral processing technology is heavy magnetite selected and flotation and strong magnetic separation or many kinds of mineral processing technology and, also had magnetized after roasting low intensity magnetic separation technology. Magnetic Iron Ore Early magnetite dressing generally more use heavy method to choose process, basically have jig, centrifugal processing machine, screw chute, spiral dressing machine, wave bed, because its dressing processing power small, the dressing low grade and low reclamation and be washed out gradually. Magnetite Mineral processing equipment Then magnetite dressing the flotation technology development and the strong magnetic separation technology, mainly oxidation paraffin wax soap of collector for the flotation is technology on electromagnetic flat ring strong magnetic separation machine dressing equipment of strong magnetic separation technology. Process Of Mining Iron Ore But its choose don't technology indexes not achieve satisfactory results. In recent years, the magnetite dressing made great progress, the main mineral processing technology is: to the electromagnetic pulsating high gradient magnetic separation machine, as a representative of the strong magnetic separation dressing craft, and as a representative of the reverse flotation series of mineral processing. Magnetic Iron Ore Especially the strong magnetic-flotation process that some of the united mine to choose don't magnetite iron concentrate grade and recovery of iron concentrate the satisfaction index.

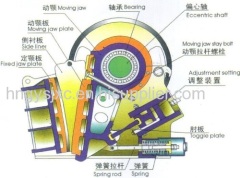

Working principle of Magnetite Mineral processing equipment :

The ore pulp wa put into the tub, the flow of water in the mine in water tank function, ore in state into the tub of loose to mining area. Magnetite Mineral processing equipment In the role of the magnetic field, the magnetic mineral grains happen together and the formation of magnetic "magnetic group" or "magnetic chain", "magnetic group" or "magnetic chain" by magnetic force in the pulp in role to poles movement, and adsorption in the cylinder. Because the polarity of the magnetic poles along the cylinder is the direction of rotation alternate arrangement, and have fixed, "magnetic group" or "magnetic chain" with the rotating cylinder , because the poles and produce magnetic alternating mixing phenomenon, be mingled in the "magnetic group" or "magnetic chain" of the gangue minerals in magnetic fall out of turn down, was eventually suck in cylinder surface "magnetic group" or "magnetic Ephraim" is concentrate. Process Of Mining Iron Ore Concentrate with cylinder turned to the edge of the magnetic force weakness, and discharge in ore washing water hoses under the action of discharge is to concentrate in the slot, if is the magnetic magnetic roller, unloaded ore is to use brush roller.

Features of Magnetite Mineral processing equipment :

Magnetic separation machine magnetic department, using quality ferrite materials or with magnets compound and into, tube table average magnetic induction strength for 100 ~ 600 mT. According to customer needs, can provide downstream, half reflux, counter-current type and so on many kinds of different table strong magnetic separation. Magnetic Iron Ore This product is simple in structure, large quantity, the operation is convenient, easy to maintenance.

Magnetite Mining suitable for:

Magnetic separation machine applicable to the size of the following 3 mm magnetite, magnetic pyrite mine, baking, titanium iron ore material such as wet magnetic separation, also used in coal, nonmetalliferous ore, building materials, and other materials for removing iron homework.

Previous:Gold Processing Equipment

Next:[Beneficiation production line]

Relevant articles:

.jpg)