|

Gongyi Mchinery Factory

|

Hammer Crusher Machine/Mang Feng Machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hammer crusher is used for crushing all kinds of medium-hardness and weak-abrasiveness materials .

Application of hammer mill crusher

Hammer crusher is used for crushing all kinds of medium-hardness and weak-abrasiveness materials whose compressive strength less than 100 Mpa and water content less than 15%, such as coal, salt, chalk, plaster, brick, limestone, etc. In addition, the hammer mill not only can be used in crushing production line and sand making production line, also can be used in mineral processing production line.

Working principle of hammer mill

Motor drives rotor to rotate at high speed in the crushing cavity.

Materials are fed into the machine from feeding port and crushed by the impacting, shearing, grinding of hammer with high-speed movement.

A sieve plate is equipped at the bottom of rotor; materials smaller than screen hole size are discharged through the sieve plate, and those greater than screen hole size are intercepted on the sieve plate for being impacted and grinded by hammer, and finally discharged outside through the sieve plate.

Classification of Hammer crusher machine

Hammer crusher machine can be classified into single rotor (single shaft) type and double rotor twin-shaft type, while, single rotor also can be divided into irreversible type and reversible type.

According to hammer rows, it can be divided into single-row type and multiple-row type.

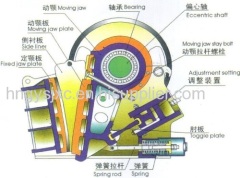

Structure of hammering machine

Hammering machine is composed of housing, rotor, hammerhead, back plate, screen plate, etc.

Features of hammer mill crusher

1. The hammer head adopts new technology, abrasion-resistance and impact-resistance;

2. Customers can adjust granularity discretionarily according to the customer's requirements;

3. Sealed structure solves dust pollution and leakage in crushing workshop;

4. The machine has beautiful shape, compact structure, less wearing parts and easy maintenance.

Technical parameters of Hammer mill crusher

| Specifications | Feeding Size (mm) | Discharging size (mm) | Capacity (m³/h) | Motor power (kw) | Total weight (t) | Dimensions (L×W×H) (mm) |

| PCΦ400×300 | ≤200 | ≤25 | 5-10 | 11 | 0.8 | 900×670×860 |

| PCΦ600×400 | ≤250 | ≤30 | 10-22 | 22 | 2.26 | 1200×1050×1200 |

| PCΦ800×600 | ≤250 | ≤35 | 18-40 | 55 | 4.8 | 1310×1180×1310 |

| PCΦ1000×800 | ≤350 | ≤35 | 25-50 | 75 | 5.9 | 1600×1390×1575 |

| PCΦ1000×1000 | ≤350 | ≤35 | 30-55 | 90 | 8 | 1800×1590×1775 |

| PCΦ1250×1250 | ≤350 | ≤35 | 35-65 | 132 | 14 | 2060×1600×1890 |

| PCΦ1400×1400 | ≤350 | ≤35 | 50-100 | 280 | 32 | 2365×1870×2220 |

| PCΦ1600×1600 | ≤350 | ≤35 | 100-150 | 480 | 37.5 | 3050×2850×2800 |

.jpg)