|

Gongyi Mchinery Factory

|

Shaking table -Mang Febg Machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Shaking table separation combines the technology of shaker and gravity concentration in China, with features of high enrichment ratio etc.

Brief introduction to shaking table separation

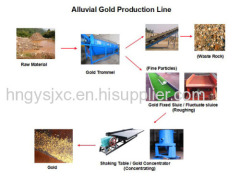

Shaking table separation is mineral processing equipment used for sorting fine material under gravity, and it's widely used in sorting tin, gold and silver, tungsten, tantalum, niobium, lead, zinc, iron, manganese, titanium, iron, coal, etc. Gongyi machinery factory has a long history in manufacturing jerking table, and continues to develop and innovate from the straight strip surface bed table to single surface bed table (early 70's), to hyperbolic wave (early 90 's), to double surface bed table, our shaking table has greatly improved its processing capacity, recovery rate, and enrichment ratio.

Performance characteristics of mineral separating shaking table

Ore Concentrator combines the technology of shaker and gravity concentration in China, with features of high enrichment ratio, high separation efficiency, simple operation and other advantages, and the final concentrate and final tailings can be got after one concentration. Compared with traditional concentrator table, concentrator table doesn't need agents, and has features of lower energy consumption, easy to manage, and high performance-price ratio.

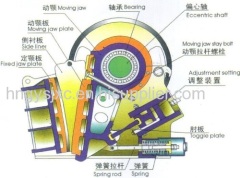

Working principle of concentrator table

Concentrator table scatters ore materials on table surface loosely by virtue of the symmetric reciprocating motion of mechanical stone plate and water current on inclined surface, so that mineral can be separated according to different densities

Technical parameters of Shaking table separation

| Name | Unit | Grit concentrating table | Fine sand concentrating table | Sludge concentrating table | |

| Dimensions | Length | Degree | 4450 | 4450 | 4450 |

| Driving part width | Degree | 1855 | 1855 | 1855 | |

| Concentrate part width | Degree | 1546 | 1546 | 1546 | |

| Max. feeding size | Degree | 2 | 0.5 | 0.15 | |

| Feeding amount | T/d | 30-60 | 10-20 | 15-25 | |

| Feeding thickness | % | 25-30 | 20-25 | 15-25 | |

| Journey | Degree | 16-22 | 11-16 | 8-16 | |

| Frequency | F | 15-48 | 48-53 | 50-57 | |

| Water quantity | T/d | 80-150 | 30-60 | 10-17 | |

| Horizontal obliquity | degree | 2.5-4.5 | 1.5-3.5 | 1-2 | |

| Portrait obliquity | % | 1.4 | 0.92 | ---- | |

| Table board corner | degree | 32-42 | 40 | 42 | |

| Concentrating square | ---- | 7.6 | 7.6 | 7.6 | |

| Table board length ratio | ---- | 2.6 | 2.6 | 2.6 | |

| Motor power | KW | 1.1 | 1.1 | 1.1 | |

Previous:Agitation Vat

Next:Disk Granulator

Relevant articles:

.jpg)